Product Description:

The SKLD series anti-corrosion intelligent electromagnetic flowmeter utilizes constant current low-frequency three value rectangular wave or dual frequency rectangular wave excitation, which not only has the advantages of rectangular wave magnetic field, but also overcomes the disadvantages of sine wave magnetic field; It can also eliminate errors caused by fluctuations in power supply voltage, changes in power supply frequency, and changes in excitation coil impedance; And it has zero stability and is not affected by fluid noise interference. Thus, it has the characteristics of good stability and high reliability. The measurement principle of anti-corrosion intelligent electromagnetic flowmeter is based on Faraday's law of electromagnetic induction. The anti-corrosion intelligent electromagnetic flowmeter consists of a sensor and a converter. The sensor is installed on the measurement pipeline, and the converter can be combined with the sensor to form an integrated electromagnetic flowmeter. The converter is installed within 30 meters or 100 meters of the sensor, and the two are connected by a shielded cable to form a split electromagnetic flowmeter. The main components of the anti-corrosion intelligent electromagnetic flowmeter sensor are: measuring tube, electrode, excitation coil, iron core, and magnetic yoke housing.

The anti-corrosion intelligent electromagnetic flowmeter is mainly used to measure the volumetric flow rate of conductive liquids and slurries in closed pipelines. Such as water, sewage, mud, pulp, various acids, alkalis, salt solutions, food slurries, etc., widely used in the production process flow measurement and control of industries such as petrochemicals, steel metallurgy, water supply and drainage, water conservancy irrigation, water treatment, environmental protection sewage total control, papermaking, pharmaceuticals, food and other agricultural sectors; Suitable for measuring the total amount of conductive liquids.

Product features:

1. Programmable low-frequency rectangular wave excitation improves the stability of flow measurement and reduces power loss;

2. Adopting a 16 bit embedded microprocessor, it has fast computing speed and high accuracy;

3. All digital processing, strong anti-interference ability, and reliable measurement;

4. Ultra low EMI switching power supply, suitable for a wide range of power supply voltage changes, with good EMC resistance performance;

5. Full Chinese character menu operation, easy to use, simple to operate, easy to learn and understand;

6. High clarity backlit LCD display;

7. It has bidirectional flow measurement and bidirectional total accumulation functions, and bidirectional output functions for current and frequency;

8. There are three integrators inside that can display forward cumulative quantity, reverse cumulative quantity, and differential cumulative quantity respectively;

9. Equipped with RS485 or RS232 digital communication signal output

10. Equipped with conductivity measurement function, it can distinguish whether the sensor is empty or not;

11. The constant current excitation current has a wide range and can be used in conjunction with different companies and types of electromagnetic flow sensors;

12. Equipped with self checking and self diagnostic functions;

13. Adopting SMD devices and surface mount (SMT) technology, the circuit has high reliability;

14. The internal design of the instrument includes a non power failure clock that can record 16 power failure times.

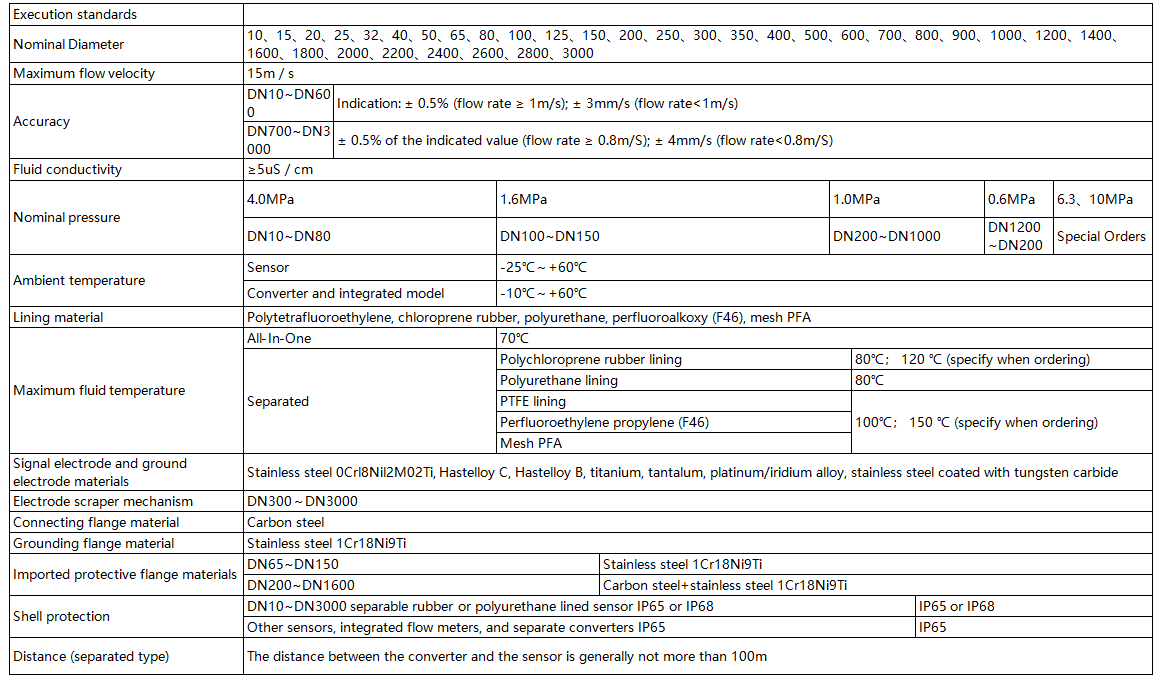

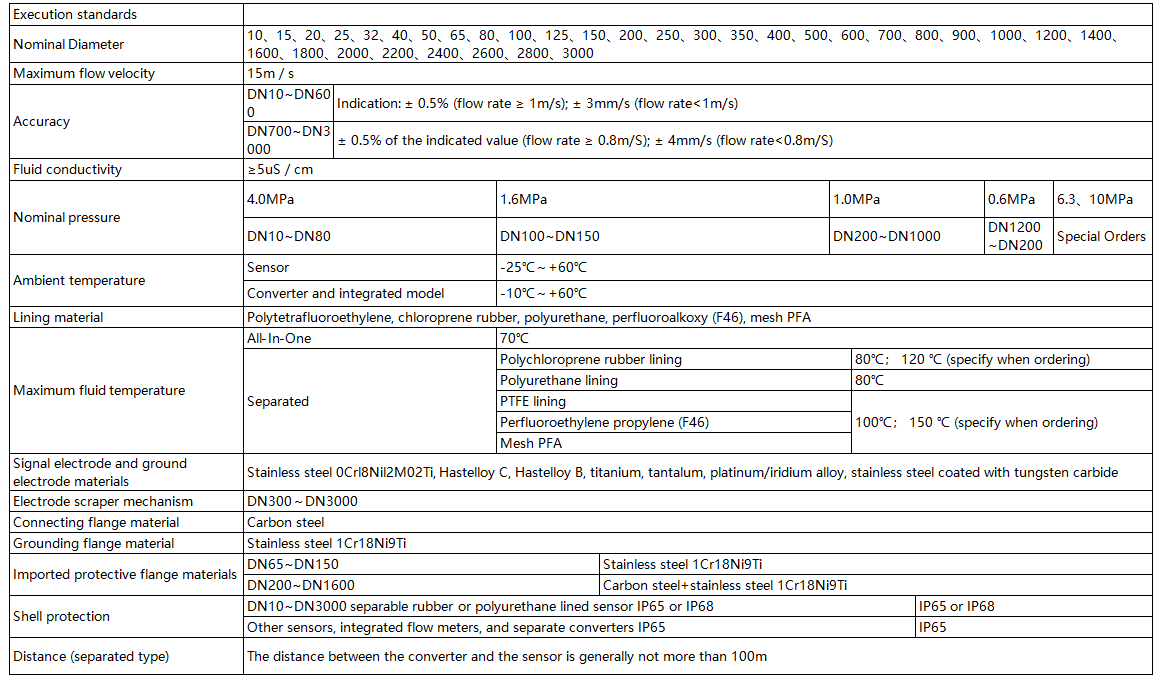

Main technical data:

Technical data of the whole machine and sensors

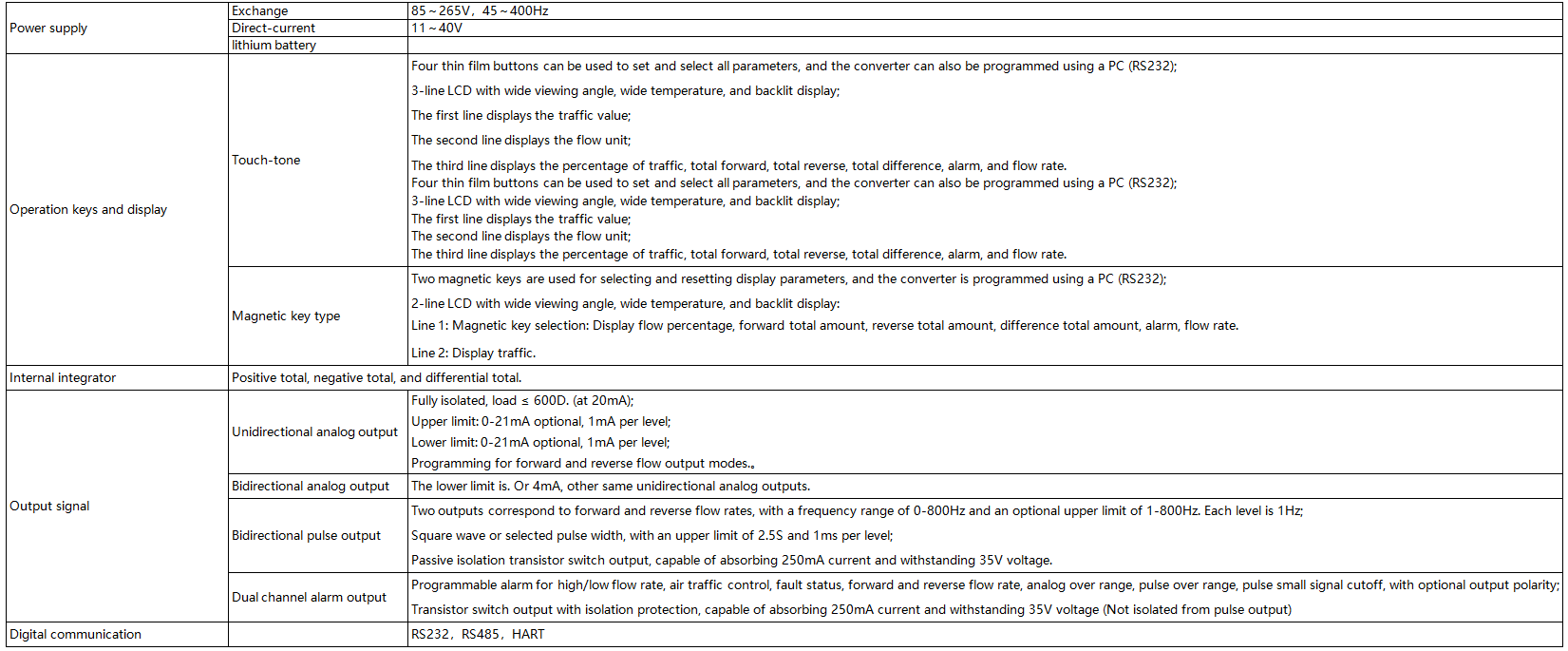

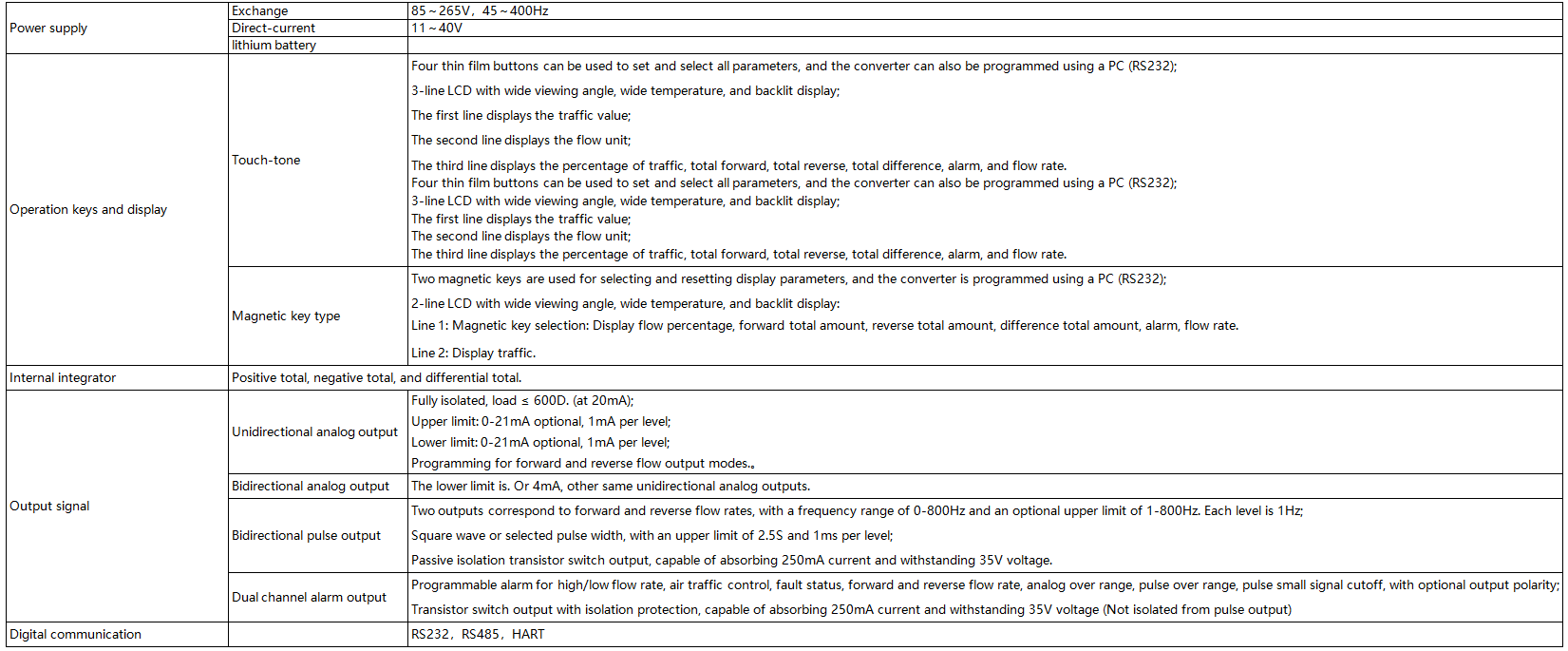

Converter technology data

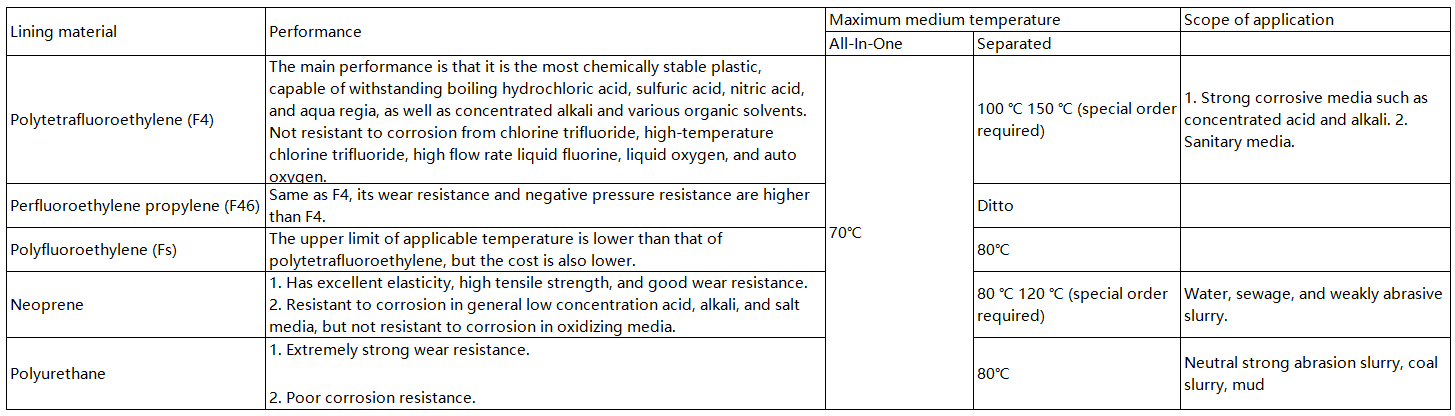

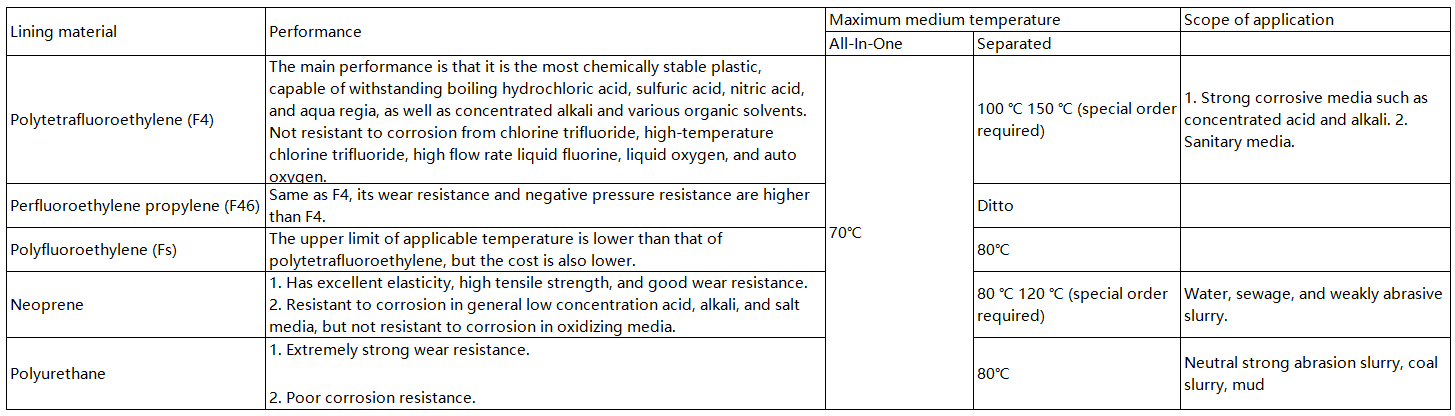

Selection of lining

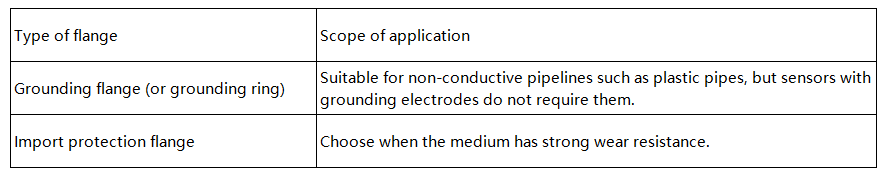

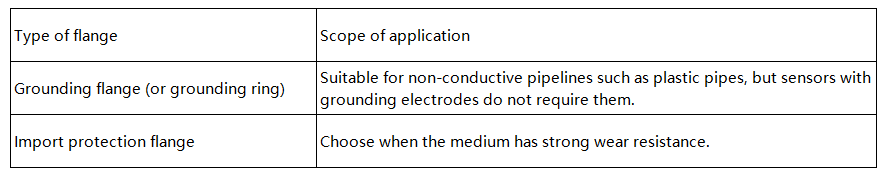

Selection of imported protective flanges and grounding flanges (or grounding rings)

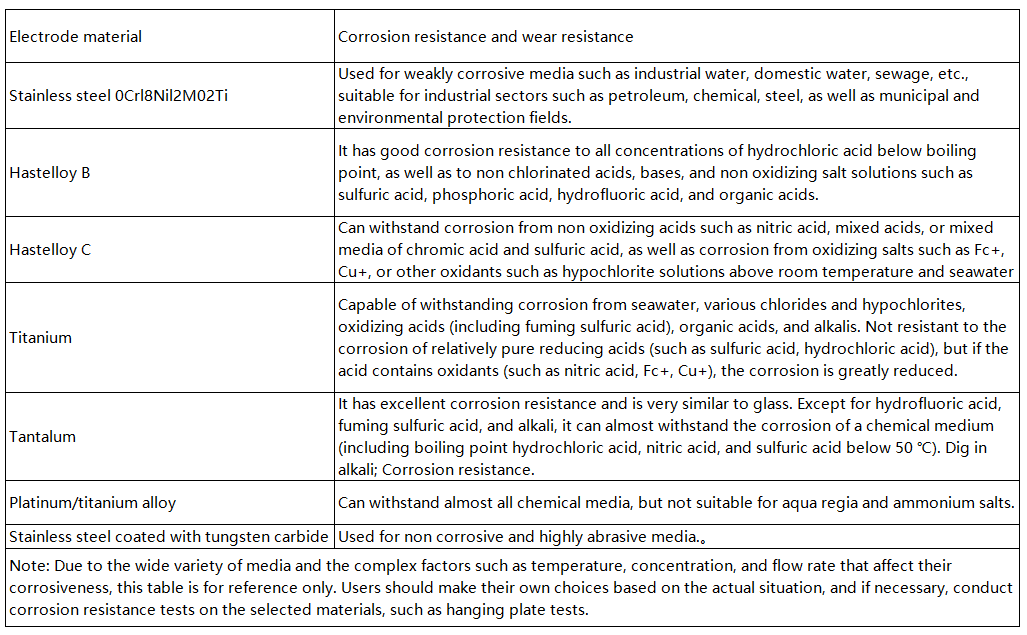

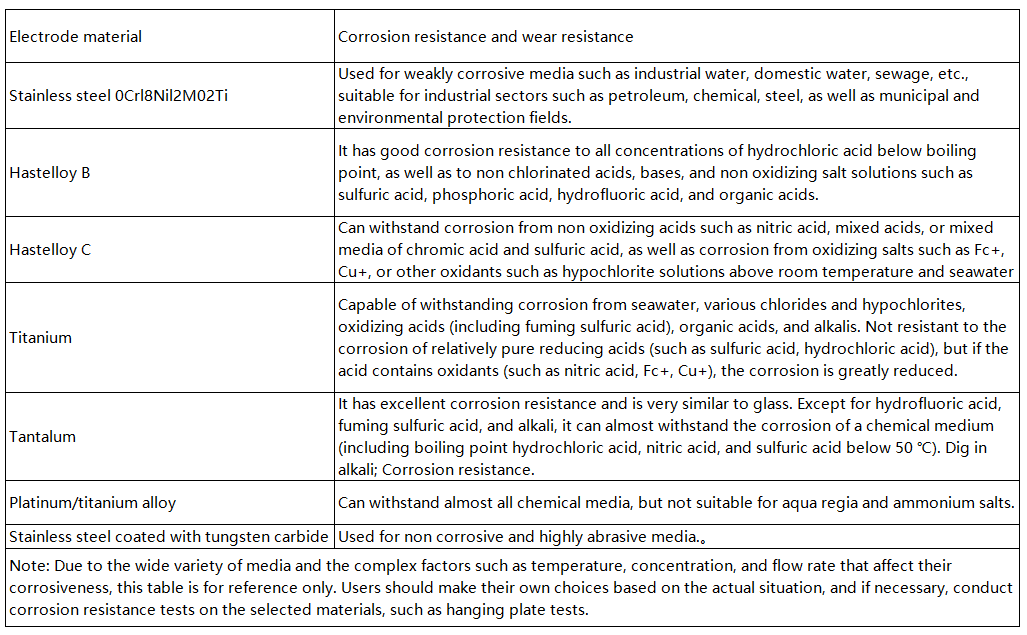

Selection of electrodes

Selection of anti-corrosion intelligent electromagnetic flowmeter

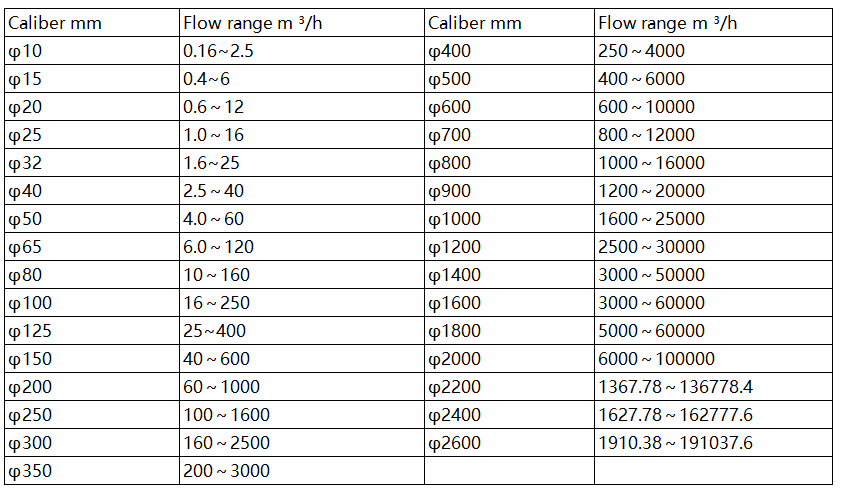

◆ Range confirmation

Generally, explosion-proof flow meters for industrial use should have a measured medium flow rate of 2-4m/s. In special cases, the minimum flow rate should not be less than 0.2m/s, and the maximum flow rate should not be less than 0.2m/s

It should not exceed 8m/s. If the medium contains solid particles, the commonly used flow rate should be less than 3m/s to prevent excessive friction between the lining and the electrode; For viscous fluids,

The flow velocity can be chosen to be greater than 2m/s. A higher flow velocity helps to automatically eliminate the effect of viscous substances attached to the electrode, which is beneficial for improving measurement accuracy.

Under the condition that the range Q has been determined, the size of the flowmeter diameter D can be determined based on the range of flow velocity V mentioned above, and its value can be calculated by the following formula:

Q=π*3600D²V/4

Q: Flow rate (m ³/h) D: Inner diameter of pipeline V: Flow velocity (m/s)

The range Q of the explosion-proof intelligent electromagnetic flowmeter should be greater than the expected maximum flow value, while the normal flow value should be slightly greater than 50% of the flowmeter's full range scale.

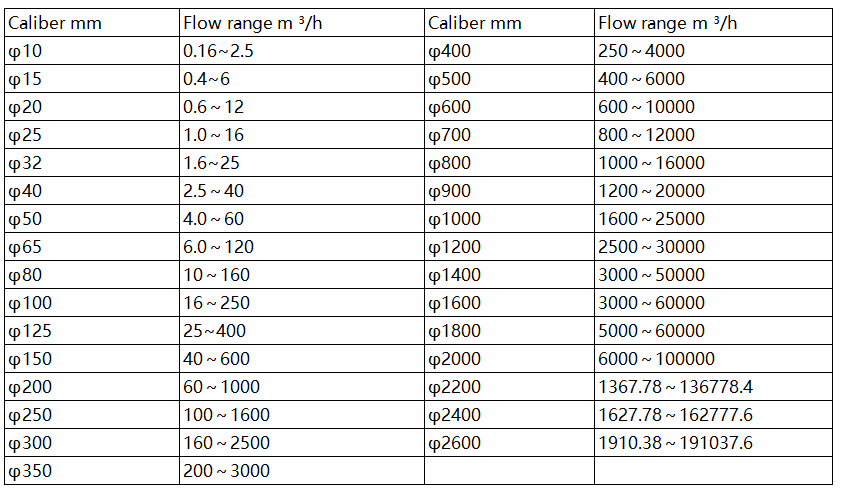

◆ Anti corrosion intelligent electromagnetic flowmeter reference flow range

Selection spectrum of anti-corrosion intelligent electromagnetic flowmeter

| Model | Caliber |

|

| SKLD | 10~2600 |

|

| Code | Installation form |

|

| Y | Integrated |

| F | Split type |

| Code | Converter model |

| ZA | Rotundity |

| ZB | Square (only applicable to split type) |

| Code | Power supply form |

| AC | (AC) 220V AC 50Hz (90~245V AC 50Hz) |

| DC | (DC) 24V DC (20-36V DC) |

| LD | Lithium battery power supply (without signal output) |

| Code | Output Signal (Multiple Choice) |

| I.4 | 4~20mA |

| f | Frequency 1KHz |

| Rs | Serial communication (485) |

| H | Hart protocol |

| C | Control output |

|

| Code | Explosion proof requirements |

| N | No explosion-proof |

| EX | Explosion-proof |

| Code | Medium temperature |

| T1 | ≤65℃ |

| T2 | ≤120℃ |

| T3 | ≤180℃(Only applicable to split type) |

| Code | Lining material |

| NE | Chloroprene rubber (≤ 65 ℃) |

| PVC | Polyvinyl chloride (≤ 70 ℃) |

| PU | Polyurethane wear-resistant (≤ 80 ℃) |

| PTFE | Polytetrafluoroethylene (≤ 180 ℃) |

| Code | Electrode material |

| 316L | Stainless steel |

| HC | Hastelloy C |

| Ti | Titanium |

| Ta | Tantalum |

| Pt | Platinum |

The electromagnetic flowmeter series products include: anti-corrosion intelligent electromagnetic flowmeter; Integrated electromagnetic flowmeter; Split type electromagnetic flowmeter; Plug in electromagnetic flowmeter; Explosion proof electromagnetic flowmeter; Split insertion electromagnetic flowmeter; Sanitary electromagnetic flowmeter